MSC Cradle CFD

Cradle CFD is easy to use, practical, advanced CFD simulation and visualization software.

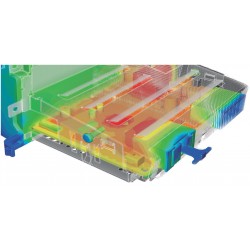

It is used for a wide variety of applications such as Automotive, Aviation, Electronics, Building and Architecture, Civil Engineering, Turbomachinery, Fan, Machinery and Marine, which have proven themselves with high processing speed, pioneering technology and high user satisfaction. It is customized for thermal and fluid problems.

It offers many differences and advantages such as mobile network applications, high-speed automatic networking capability, transferring almost any CAD data, cleaning and editing CAD data, and working in integration with other products of MSC.

MSC Cradle CFD product family includes computational heat-flow analysis software such as scFLOW, SC / Tetra, scSTREAM.

scFLOW

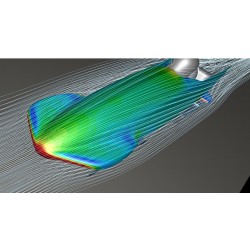

scFLOW is a next generation CFD software that uses unstructured mesh to accurately represent complex geometries.

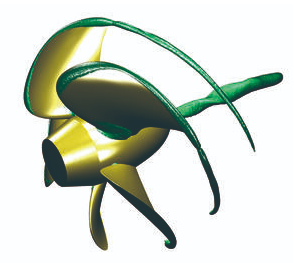

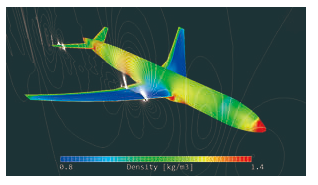

scFLOW, with pre-processor that helps users of all levels to produce a high-quality element network and create complex models, together with the solvent that provides high stability and speed, aerospace and automotive aerodynamics, the performance of rotating equipment such as fans and pumps, design problems of electronic devices, multiphase used to solve problems.

Thanks to the joint simulations (Co-Simulation) integrated with MSC software Marc, Nastran, Adams and Actran, more realistic results can be obtained with interdisciplinary analyzes on subjects such as fluid, structural, acoustic and multi-body dynamics.

scFLOW Features

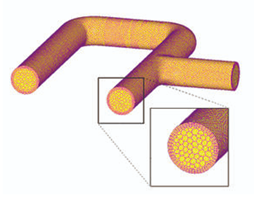

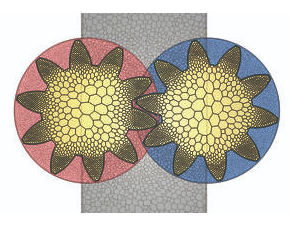

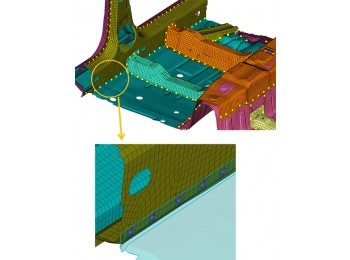

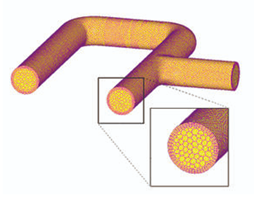

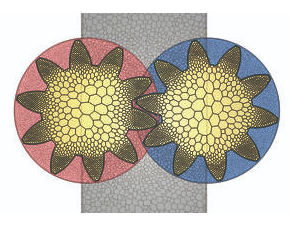

Polyhedral Mesh

Can represent a model to be analyzed using two different networking methods:

Among these methods, the polyhedral network structure shortens the analysis time and provides more stable and accurate results.

In the network structure thrown by the voxel method, curved and curved surfaces are represented as a cube.

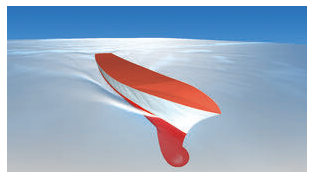

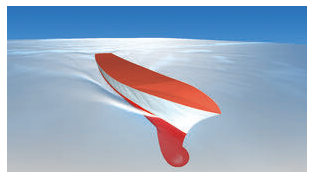

Free Surface

scFLOW, the shape of the interface between a gas and a liquid can be simulated. Calculations made with the fluid volume method (VOF) are faster and more consistent.

In addition, it can be used with functions in the software such as "overset" network and particle monitoring, which is a mobile network structure.

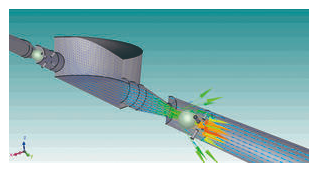

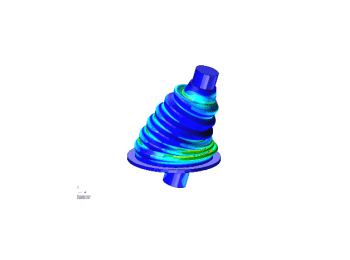

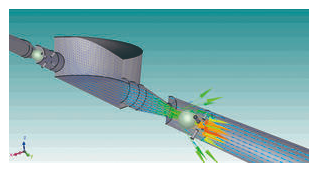

Moving Mesh (Discontinuous Mesh / Overset Mesh)

The discontinuous network function is a feature that is used in a wide variety of ways, from the analysis of the slip heating generated between the rotor and the pad of a brake disc, to the analysis of rotation and translation combinations such as a piston pump.

In this context, it uses "Discontinuous" network for rotating parts and "Overset" network structure for parts that make both rotation and displacement.

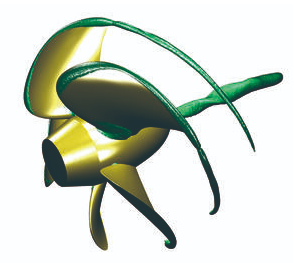

Freedom-Degree Analyzes

With this function, the user can analyze a rotating propeller or a free-moving part due to the flow, taking into account the 6-degree of freedom rigid body motion (3-dimensional advance + 3-dimensional rotation).

Cavitation

With this function, the cavitation that occurs on the propeller rotating at high speed in a liquid can be calculated. Cavitation occurs when the pressure of a liquid is lower than the pressure around it. scFLOW also supports solving problems caused by cavitation such as erosion.

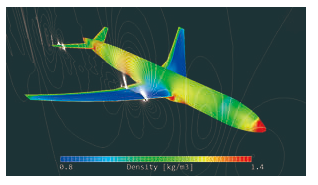

Compressable Flow

The scFLOW can analyze phenomena such as supersonic flow as well as significant expansion / contraction of fluid volume. Two pressure-based and density-based solvents can be used for compressible flow problems.

With the density-based solvent, stable results can be obtained even at high Mach numbers.

Depending on the problem and the analysis goal, one can choose any of the solvers.

Evaporation / Condensation

The free surface analysis function of the software (VOF method) can simulate phase change problems such as evaporation and condensation between gas and liquid.

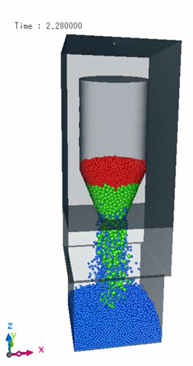

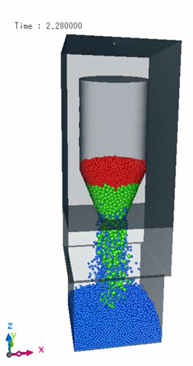

Discrete Element Method-Dem

Using the inter-particle forces (DEM) and particle tracking function, it can analyze the problems where the fluid flows from a particle filling such as fluidized bed and powder transport.

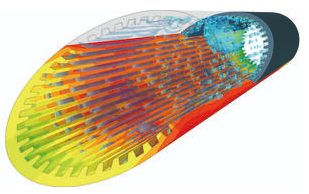

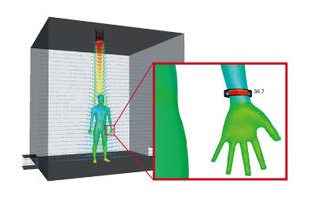

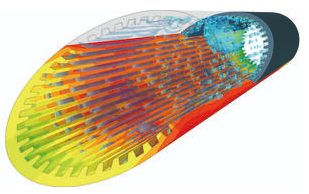

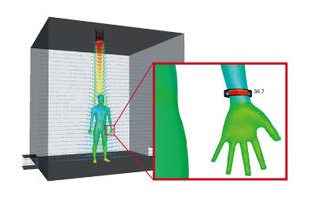

Thermoregulation Model (Jos)

By using the thermoregulation model (JOS) and flow analysis together, the surface temperature of the human body in a particular thermal environment can be analyzed.

In addition to environmental conditions such as temperature and speed, the user can use parameters of the human body such as age, clothing and blood flow.

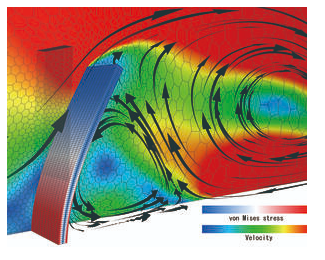

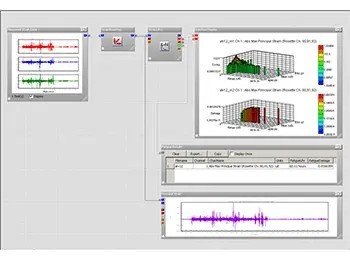

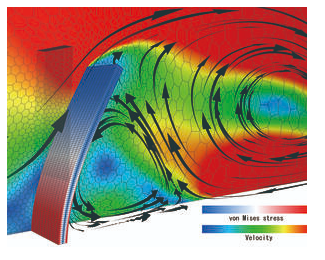

Common Simulation With Msc Software Products (Co-Simulation)

Through simultaneous co-simulations with MSC software Marc, Nastran, Adams and Actran, fluid, structure, acoustic and multibody dynamics problems can be modeled more realistically, the physics of the problem can be analyzed in more detail and more accurate results can be obtained.