Electro-Dynamic Vibration Test Systems

Dongling Vibration, the parent company of DONGLING TECH GROUP, draws attention as a company preferred by leading industrial enterprises with its solutions for vibration test systems. As of 2010, it has proven its worth as the manufacturer of the highest driven (350 kN) vibration test system ever produced in the world, producing 450 kN in early 2012, 500 kN as of July 2012 and 600 kN in 2015. DL is one of the few companies in the world that produces a vibration test system that applies a load of 16 tons or more. It is the only company in the world that can reach 30 tons or more with a single shaker. DL is an OEM manufacturer of the company that supplies many vibration test systems - shakers.

There is no need for seismic block construction in DL vibration test systems up to 70 kN. Thus, before the vibration test systems are placed in the laboratory, there is no need for a special building design or an additional construction in the laboratory of the existing building and construction costs are saved.

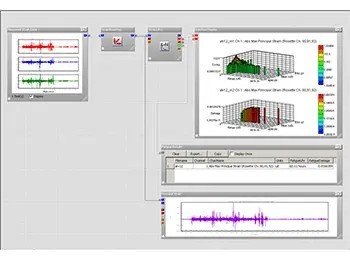

New industrial design and remote controlled touch screen control units with high ease of use attract appreciation and attention. It is possible to start, stop and control the relevant test studies from the office environment without the need to be in the laboratory environment.

DL product Power Amplifiers produced with IGBT technology can easily work with different brand vibration test systems used by companies. Companies that supply DL Power Amplifier can reduce energy costs and therefore business leaders, and achieve a stable and reliable solution that is much easier to maintain / repair and takes a shorter time, thanks to this investment.

Solutions

- Single axis shakers

- Three axis shakers

- Air Cooled: 1 - 70 kN, 51-76 mm displacement (option up to 100 mm)

- Water Cooled: 50-600 kN, 51-76 mm displacement (option up to 100 mm)

- Horizontal Table Series (Slip Table, Dual Slip Table)

- Vibration isolating shakers that do not require seismic block construction

- Ex-proof shakers (shakers with measures taken against creating the risk of explosion in the environment)

- Shakers for Clean Room

- Head expander

- IGBT amplifier

- Combo systems (Climatic cabin vibration test systems)

- Dual (Dual, Conjugate, Synchronous) shakers: Missile, rocket, etc. for systems

- 6 degree of freedom electro-dynamic shakers (6-DOF shakers)

- Underwater vibration system (for submarines, Submarine shaker)

Mechanical Shock Test Systems

Since almost all of the vertical shock systems have their own vibration isolators, products are offered with high cost effectiveness without the need for seismic block manufacturing and related construction costs. In addition, high shock test systems required by the industry are produced with castimizations that push the boundaries and standards.

Hydraulic, pneumatic test systems, drop test, impact test systems, bump test, inclined drop and package drop test systems are also included in the product portfolio.

In addition, it is the world's leading manufacturer of Ship Shock Test Systems in accordance with MIL-STD-810G and MIL-S-901D standards. With advanced production and rapid product development and R&D facilities, specific and intentional solutions can be offered.

Solutions

- Vertical, Horizontal, High Shock Test Systems

- Impact, Drop, Series-Intermittent Bump Test, Inclined Test Systems, Package Drop Test Systems

- Shock Response Spectrum Machine

- Ship Shock Test Systems (MIL-S-901D):

- Lightweight Shock Testing Machine

- Mediumweight Shock Testing M

After Sales Service

BİAS Engineering; It is the first company that can offer domestic environmental test sample sales, installation, maintenance-repair services such as shaker, shock test system, centrifuge test system. After-sales services are fast and following the path, customer satisfaction is at the highest level. For problems that arise in Dongling products, 7-24 technical support can be provided, 2 days of service can be arranged, and periodic maintenance schedules are monitored and controlled by us. With its domestic, fast and effective after-sales services and high product quality, Dongling products have reached the conditions that make a difference in the market.