Dantec Dynamics has been developing integrated measuring systems for diagnosis and research on fluid mechanics, solid mechanics, microfluidics, spray analysis and combustion technology for over 60 years.

It offers solutions in fluid mechanics with 4 different methods as PIV, LIF, LDA and CTA.

Particle Image Velocimetry

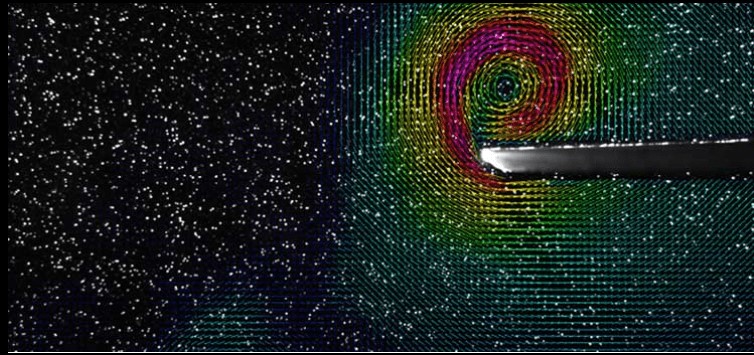

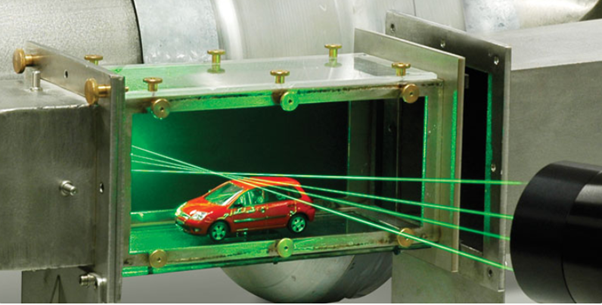

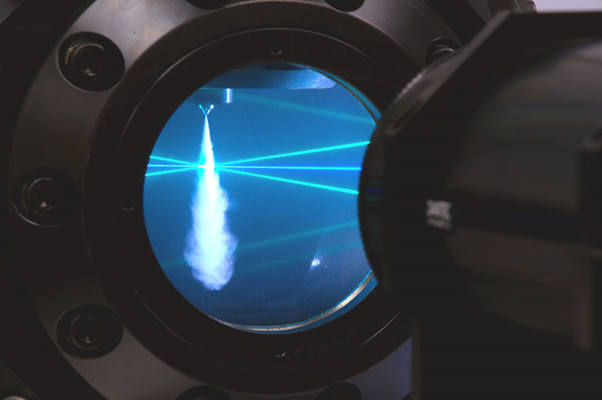

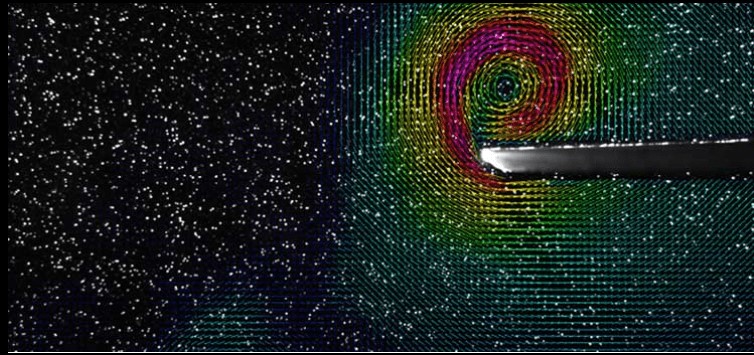

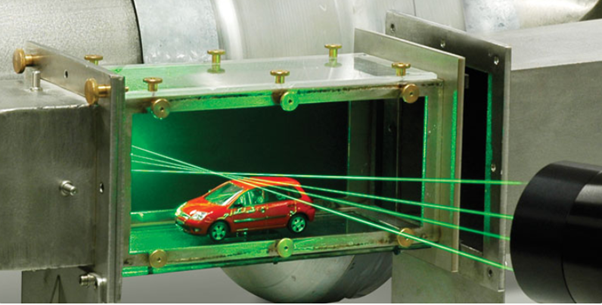

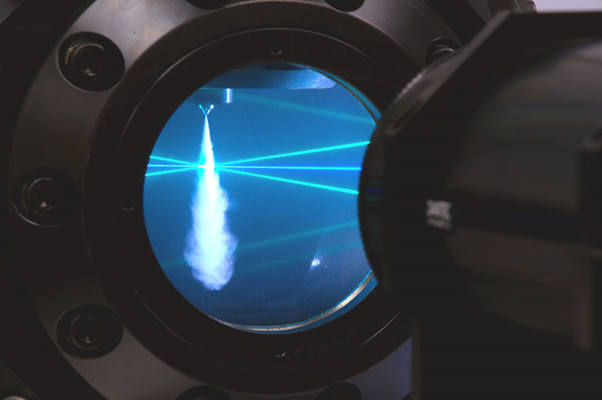

Particle Image Velocimetry (PIV) is a non-intrusive laser optical measurement technique for research and diagnostics for flow, turbulence, microfluidics, spray atomization and combustion processes. The PIV system is used in internal and external flow studies in many areas, from research on basic fluid dynamics to product development and optimization studies.

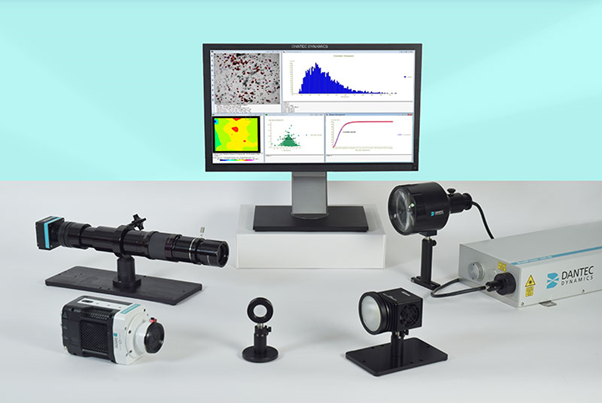

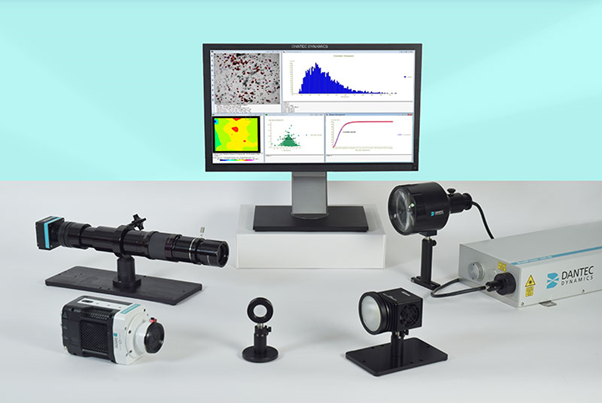

Dantec Dynamics offers a range of PIV solutions to suit a variety of research needs. Basic systems use a single camera to measure two velocity components in a plane. More advanced systems use multiple cameras to measure three velocity components in a plane or volume.

High speed systems are available to study vortices. In addition, advanced features such as uncertainty estimation and propagation providing information on measurement quality, advanced post-processing routing for vortex detections, combined PIV / LIF / Shadow measurement and pressure calculations help you get the most out of your data.

CLICK for detailed info

Wind tunnel, water tunnel, vehicle aerodynamics etc. It is widely used in interior and exterior flow applications.

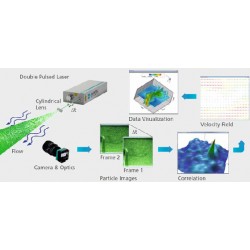

Working Principle of PIV System

Velocity components in the desired volume or plane can be measured using the PIV system. The velocity components of the fluid are calculated by taking two consecutive photographs of the laser-illuminated surface. Velocity components are obtained by applying the cross-correlation method between the two photographs taken.

In order to make the flow visible, a fog or smoke generator is used for measurements in air, and a particle is used for measurements in water. With a single camera, two speed components can be calculated from one surface, and the third speed component can be calculated using a second camera.

PIV System Capabilities

PIV is a non-intrusive technique that measures the velocity of micron-scale small particles following flow.

With PIV systems that can be applied to any velocity range, from microscopic flows to supersonic flows:

- Instant vectorial speed map

- Streamlines

- Vorticity

- Statistics and turbulence measurements

- Time resolution measurements can be made.

With the flexible grid (mesh) design, the results are similar to Computational Fluid Dynamics (CFD).

PIV System Solutions

2D & 3D Stereoscopic PIV

Standard PIV systems used for two or three dimensional flow analysis.

Two-Phase Flow

The system makes it possible to work on two-phase flows (eg measurement for boiling water) with the addition of some accessories and software on top of the main PIV systems.

Time Resolved PIV

TR-PIV systems were first introduced by Dantec Dynamics. The system consists of a fast camera and a laser. This method enables dynamic behavior to be analyzed more deeply in time resolution and animated flow.

MicroPIV

The MicroPIV system is designed for use in microscopic flow research. Experimental results are very important in such studies, especially because CFD software does not give correct results in microscopic channels.

Volumetric PIV

With the use of three or more cameras, the flow area within a volume can be examined.

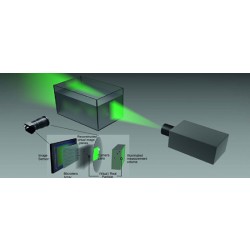

LIF (Laser Induced Fluorescence)

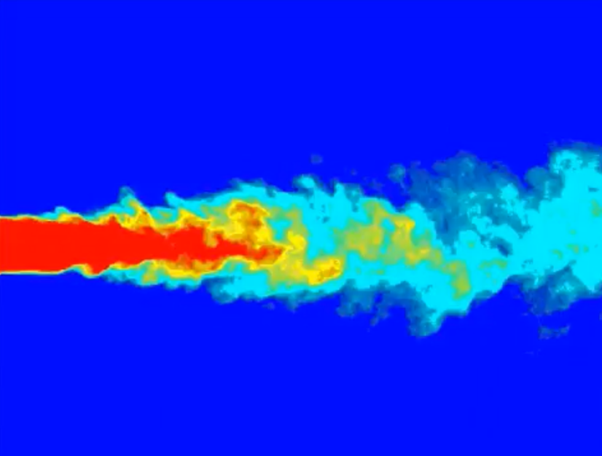

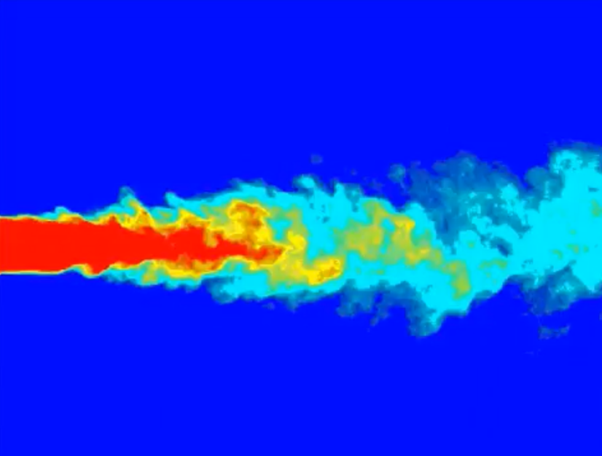

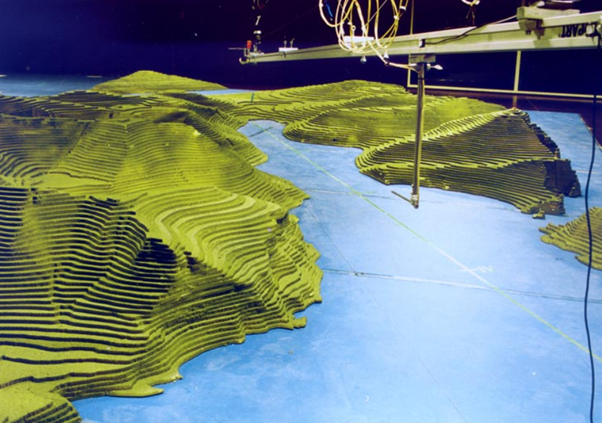

Planar laser-induced fluorescence (PLIF) is an optical diagnostic technique widely used in liquid and gas applications. PLIF has proven to be a valuable tool for flow visualization as well as for quantitative full-field measurements of concentration and temperature in liquid and concentration in gas streams. Applications can be found in process engineering, biomedical engineering, and fluid dynamics research.

With Dantec Dynamics planar LIF solutions, quantitative information can be obtained in many applications, including:

- Mixing performance of chemical processes

- Large-scale and smaller-scale interaction in turbulent mixing

- Distribution of pollutants in model ocean systems

- Heat transfer phenomena in heat exchangers, pumps and other devices to improve device performance and equipment design

- Temperature distribution in fluids of engineering interest such as foodstuffs and dyes

- By adding a fluorescent tracer type (eg Acetone) to a non-fluorescent fuel or gas, visualization of the gas phase mixture and quantitative concentration measurements can be done via LIF. A common application is fuel visualization in the development of combustion engines, where LIF allows diagnosis of the pre-combustion and combustion process.

- Dantec Dynamics' powerful yet easy-to-use system dedicated to gas phase monitor-LIF enables exploration of features such as:

- Fuel distribution

- Ignition events

- Fuel injection behavior

- Gas phase mixing studies

CLICK for detailed info

Laser Doppler Anemometry (LDA)

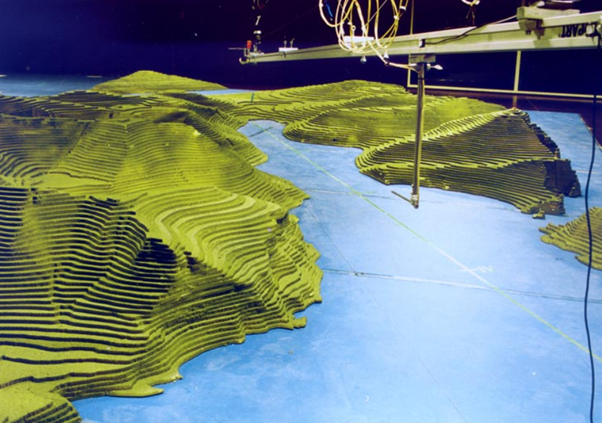

Laser Doppler Anemometry (LDA), also known as Laser Doppler Velocimetry (LDV), is an ideal optical technique for non-invasive 1D, 2D and 3D point measurement of velocity and turbulence distribution in both free flows and internal flows.

Researchers in science and industry are using our LDA systems to better understand fluid mechanics. Measurement results are important steps for fine-tuning product designs to increase aerodynamic efficiency, quality and safety.

CLICK for detailed info

Constant Temperature Anemometry (CTA)

Constant Temperature Anemometry (CTA), also known as Thermal Anemometry, is a technique for measuring turbulence in gas and liquid flows in 1D, 2D or 3D using hot wire or hot film probes placed in flow.

CTA is particularly suitable for the measurement of flows with very rapid fluctuations (high turbulence) at one point and for the study of flow microstructures where small flow eddies must be resolved to a tenth of a millimeter.

CLICK for detailed info

Spray and Particle

We offer spray and particle measurement solutions based on imaging and spot measurement techniques.

Phase Doppler Anemometry (PDA)

Our Phase Doppler Anemometry (PDA) systems measure the size, velocity and concentration of spherical particles, droplets or bubbles suspended in gas or liquid streams. PDA is also known as Particle Dynamics Analysis or PDPA.

A very common PDA application is the analysis of atomized liquids (sprays) in fuel injection, spray paint, liquid metal spray and pharmaceutical sprays.

Shadow Sizing

DynamicStudio Shadow Sizer measures the size, shape and velocity of particles using backlighting and image analysis software.

Shadow Sizer can measure a wide variety of particle types including bubbles, liquid droplets, solid particles and any object with a well-defined contour.

The data is analyzed by DynamicStudio and includes histograms of size distribution, spatial distribution plots, cumulative histograms and tables.