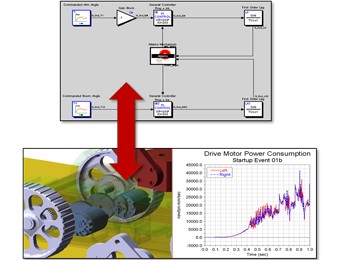

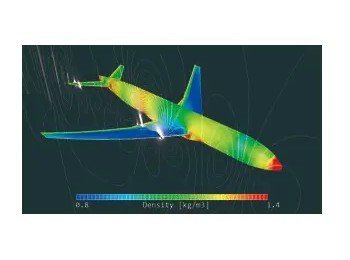

After preliminary and detailed design of a turbomachinery, it is good practice to use more accurate models and check their flow, which will be carried out later and before proceeding with tests; This short description can be conveyed that fluid dynamics come into play.

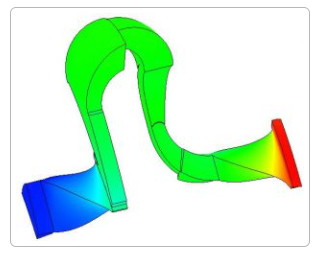

With the AxCFD module, a solution can be made in 3D with RANS model.

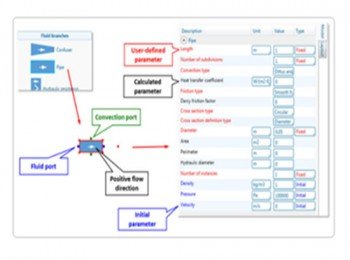

Pre-Processor

Thanks to the integrated architecture of AxSTREAM® software platform geometries, boundary conditions, clearance values, number of blades, rotation speed etc. automatically taken from the AxSTREAM® project. Thus, the errors that may arise from the user are minimized, while the pre-processor significantly simplifies and reduces the setup time. Similarly, periodic conditions as well as inlet and outlet surfaces are automatically created according to the geometry taken from the AxSTREAM® project.

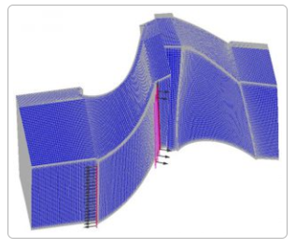

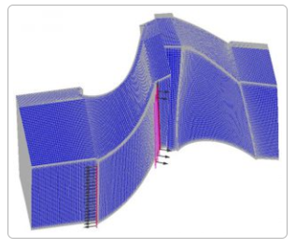

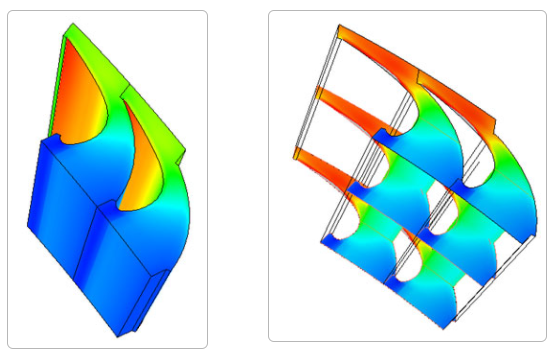

An automated turbomachinery specific structured hexagonal mesh is available with customizable meshes for the compute area zone. Different types of netting are also available, and improvements to the mesh can be made in all directions, boundary layers and rotational zones.

Solvents

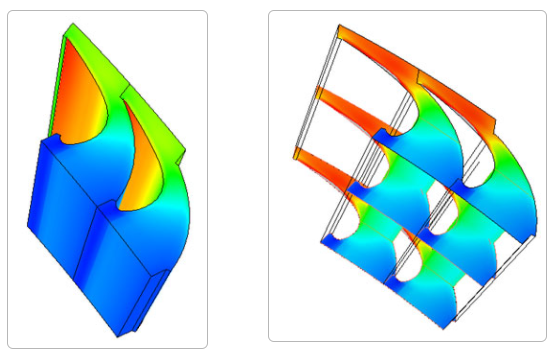

Different problem formulations are available, depending on whether the user wants to calculate a pressure value (inlet or outlet) or a machine mass flow rate. Viscosity and different turbulence models (including k-ε, k-ω, k-ε RNG, k-ω SST) can be used for new calculations or to maintain existing ones. The heat transfer between the blades and the liquid can be taken into account together with the material surface roughness. Each calculation can be run for an axial symmetric slice or for a specific span position (radial section) for all 3D geometry.

Finisher

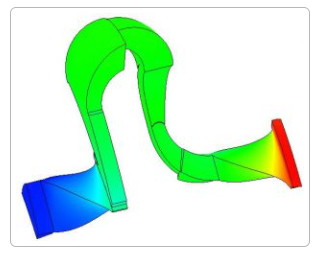

Once the calculation converges, pressure, temperature, velocity, Mach number etc. Contours can be visualized, contours and vectors can be displayed on desired surfaces and planes.

Finally, exporting CFD results allows comparisons in design and non-design conditions between different calculations using the same or different solvents (1D, 2D, 3D) as well as experimental results.