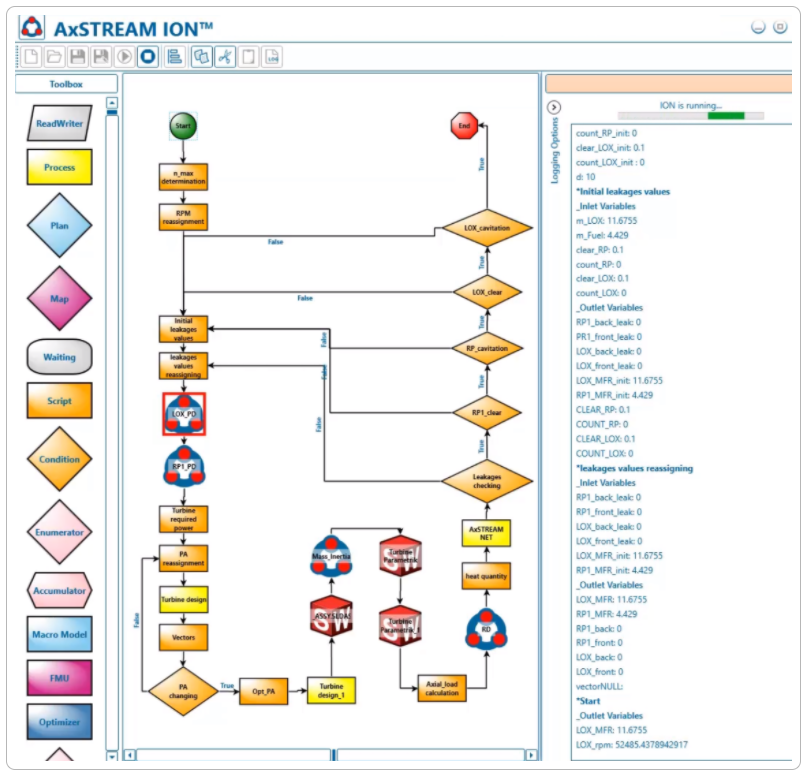

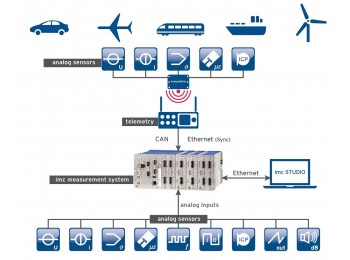

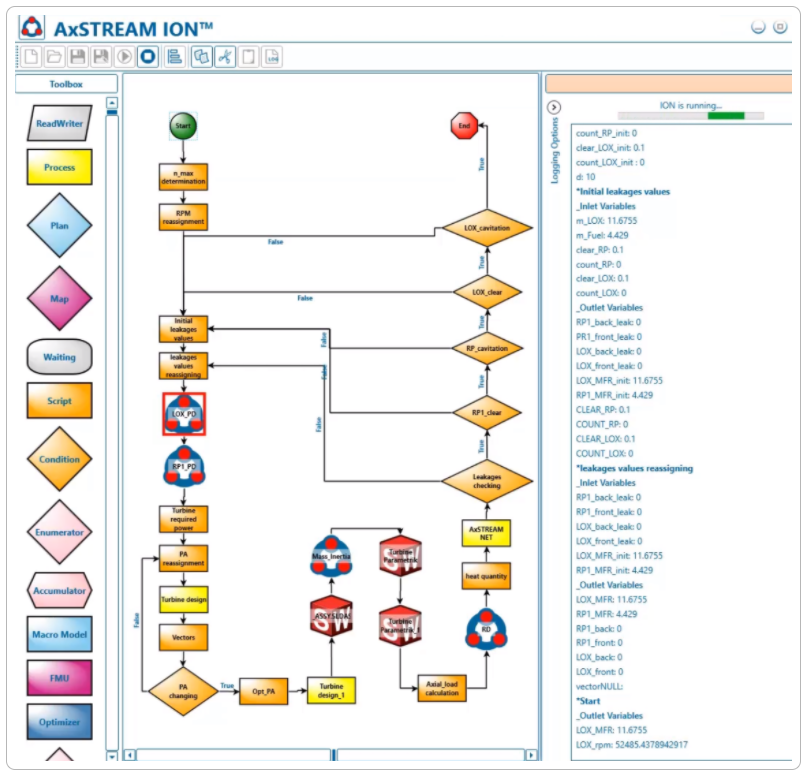

AxSTREAM ION module is a tool that integrates and automates a whole design process in a single tool, can achieve the best result by exchanging information between analysis and design according to real world conditions, and integrates different programs within different programs. It provides faster and more effective results by using artificial intelligence and machine learning subjects compared to traditional approaches. Thanks to the optimization algorithm embedded in it, it can make a prediction for simulation results by performing interdisciplinary optimization and data analysis.

Integration, Automation and Parallel Processing:

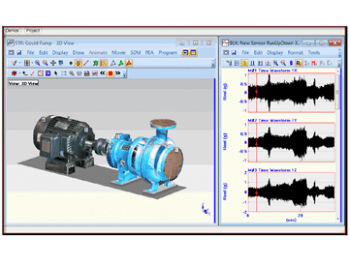

AxSTREAM ION ™ enables integration of all existing AxSTREAM resolvers and commercial software. Using AxSTREAM ION, data is automatically retransmitted to different software programs. User-defined tasks can be performed between design and analysis steps without the need for any additional coding. Thus, the margin of error is minimized in matters such as selecting the wrong input file and choosing incompatible software with the most human error.

Automation through AxSTREAM ION enables the implementation of an integrated, streamlined process for performing complex parameter studies and system response analysis. In addition, AxSTREAM ION users have parallel execution access that allows them to simultaneously schedule, automate and run larger and more complex design tasks.

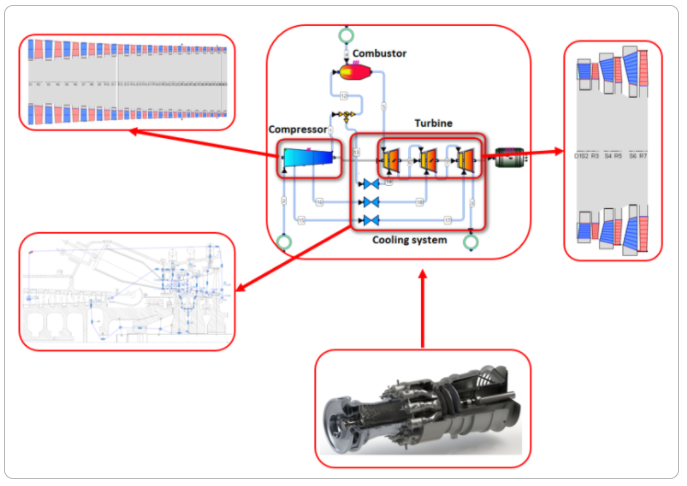

Multidisciplinary Optimization (MDO):

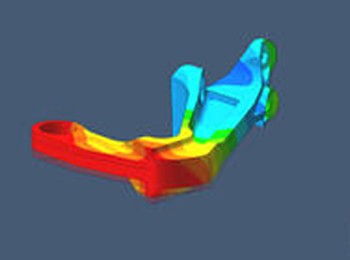

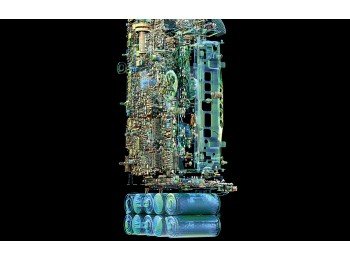

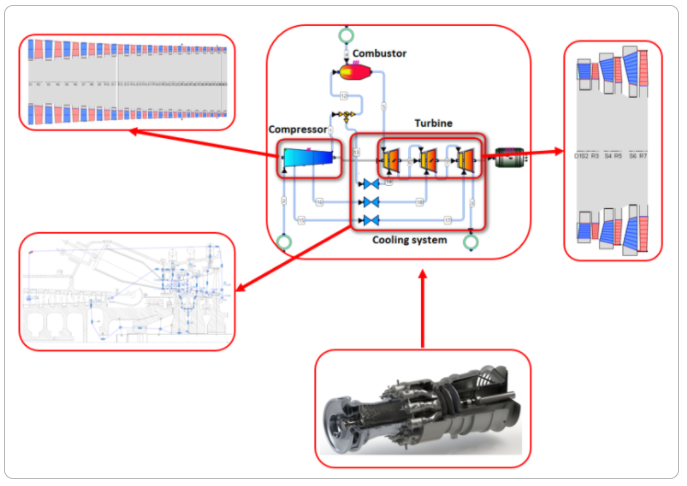

Technology development and industry becoming more competitive have caused teams to no longer work independently from each other and consequently companies have turned to multidisciplinary design optimization methods. AxSTREAM ION has built-in optimization algorithms that enable analysis and optimization across disciplines such as fluid dynamics, structural dynamics, thermodynamics and acoustics with shared data analysis in a single environment.

In this way, AxSTREAM ION allows companies and teams to make informed design decisions during the design process, allowing them to reach better products faster with less iterations and lower development costs.

AI and Machine Learning:

AxSTREAM ION can use machine learning to get insights from the simulation data generated. AxSTREAM ION has a unique ability to predict ideal configurations, boundary conditions and operating conditions to help guide users through the design process with remarkable speed and accuracy. Using machine learning to eliminate mundane tedious tasks, engineering teams have the capacity to work on new and cutting-edge concepts and then evaluate them in an independent digital environment, without sacrificing employee time and resources.

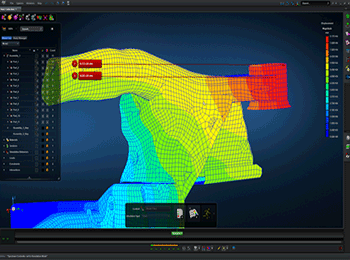

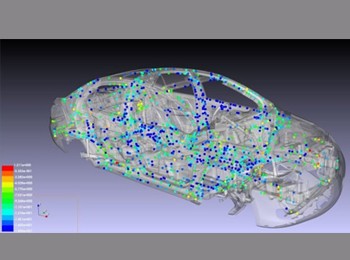

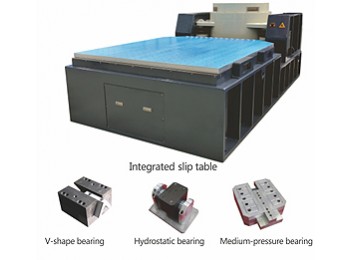

Lifetime Prediction:

AxSTREAM ION can be used to model a machine at all stages of its lifecycle, to track the reliability and successful operation of any turbomachine at every stage, whether it is new from the OEM or at the end of its life cycle. With AxSTREAM ION, users can easily visualize the digital version of the machine to investigate reliability and equipment service life against real world operating conditions. As a result, the lifecycle of a machine helps to make useful predictions through its ability to predict maintenance intervals, predict downtime due to mechanical failures, and speed up diagnostic processes.