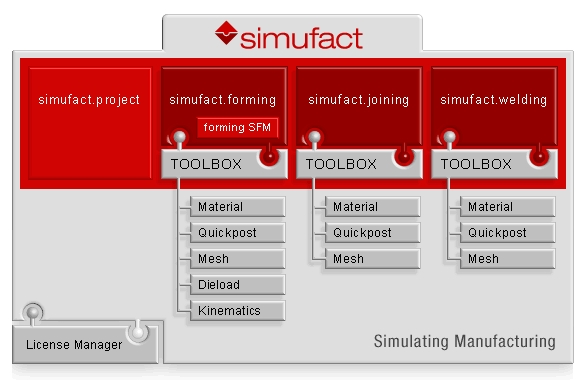

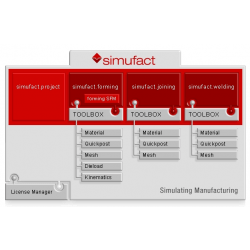

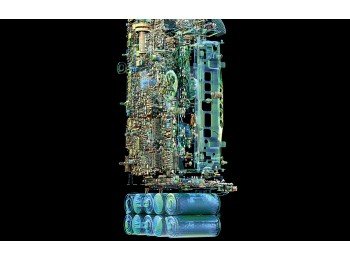

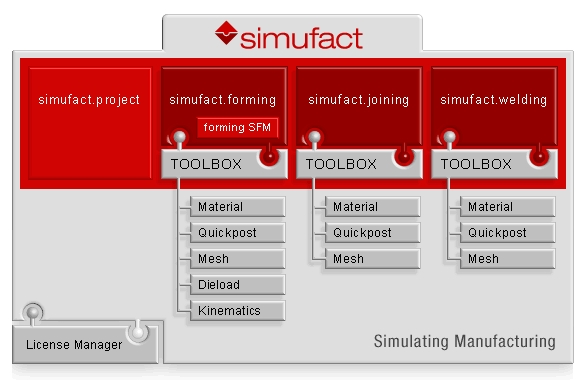

Simufact is a finite element software specially developed for the metal forming industry. Cold, warm and hot with this software supported by MSC Software, the industry's largest company in finite elements; It is possible to perform volumetric and sheet metal forming simulations in the most realistic way. The Simufact family includes many programs developed for different analysis types.

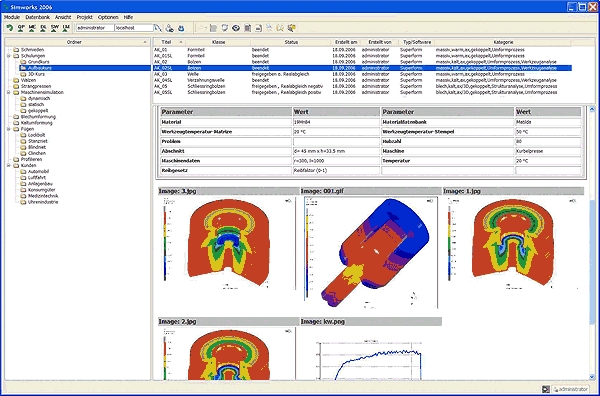

Simufact Project

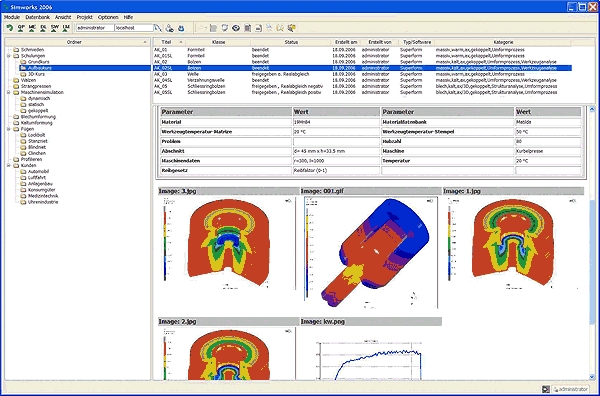

It is a general working platform that is used to keep track of all analyzes, archive, quickly access pictures, animations and other analysis results.

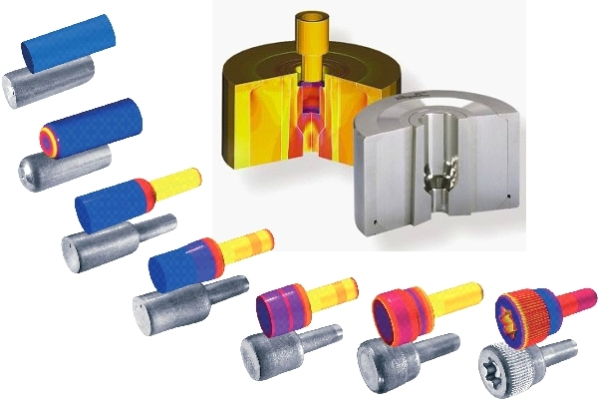

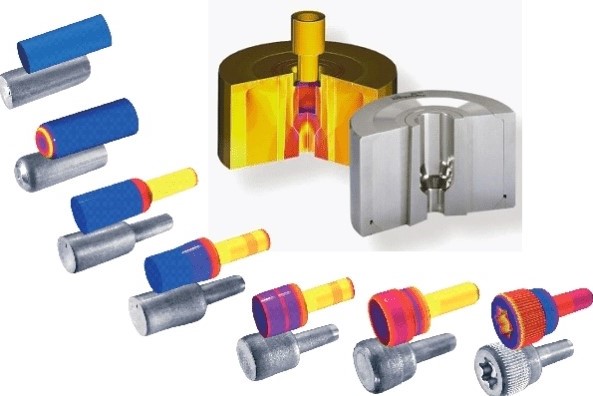

Simufact Forming

Any metal forming process can be simulated. Examples of these are extrusion, drawing, compression, bending, closed or open die forging, rolling and orbital forming. Mechanical, hydraulic, eccentric and screw presses can be used in these analyzes.

Simufact Joining

All mechanical joining processes such as riveting can be analyzed.

Simufact Welding

It has been developed for analyzing welding operations. Complex welding processes can be easily modeled with its convenient interface.

Simufact Material

It is a material data bank that brings together the physical and thermal properties of more than 300 materials. In addition, it enables the entry of the required material properties for structural, hardness and granular analysis of the material.

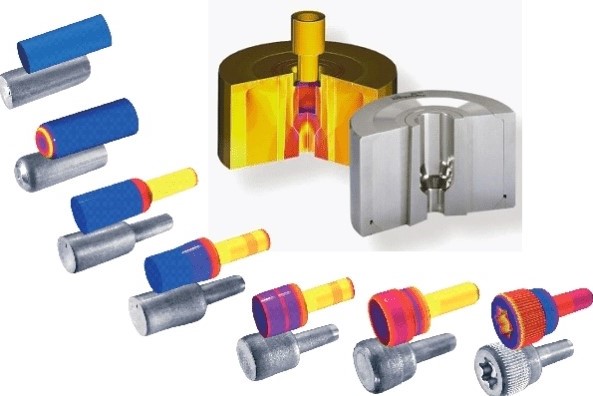

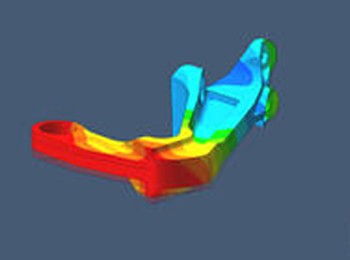

Simufact Dieload

It is a module especially used in analyzing complex 3D molds. The forces generated during shaping are transferred onto the mold and the resulting stresses are calculated.

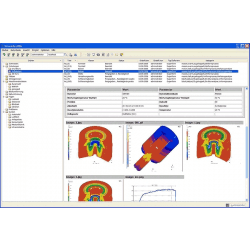

Simufact Quickpost

It is a module that is used to graph parameters such as temperature, force, strain and strain depending on variables such as time and impact motion in order to examine the analysis results more efficiently.

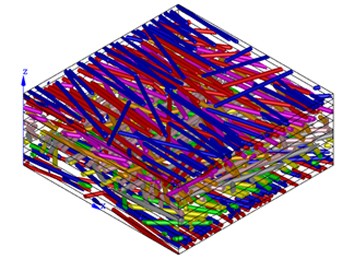

Simufact Mesh

It enables 2 and 3 dimensional parts to be divided into desired elements in the most precise way.

Simufact Kinematics

The movements of the machines used in processes such as ring rolling, circular crushing and orbital shaping can be easily defined and transferred to the simulation.

Simufact Product Family

Simufact Project Interface

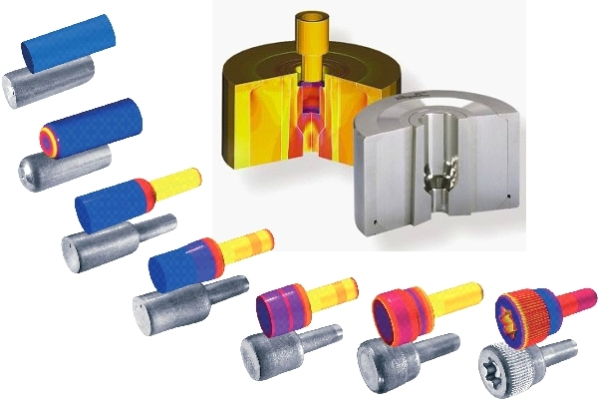

Forming and Mold Analysis