FTI FormingSuite® is our new simulation package that has recently joined the MSC Family and will support you in every step of your sheet metal forming processes. Since 1989, FTI has been offering easy and fast solutions to the design, planning and cost processes of manufacturers in sectors such as aviation, automotive and white goods.

It plays an effective role in improving the operations of OEMs and suppliers, from cost analysis and quotation of parts that may be new product candidates, to shortening the design-production processes in the most effective way.

Scope of Application

Cost analysis, feasibility and bidding studies.

Cost reduction - cost optimization processes.

Product and mold design. Anticipation and correction of possible errors in the product.

Reducing the design and new product processes to the shortest time.

Planning of processes. Time-dependent cost optimization.

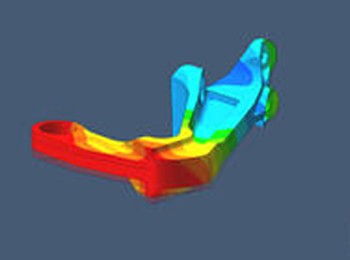

Cost Analysis

With the "COSTOPTIMIZER" module, you can effectively anticipate your risks and costs, improve your feasibility and bidding processes, as well as achieve weight and cost optimization by reducing material usage.

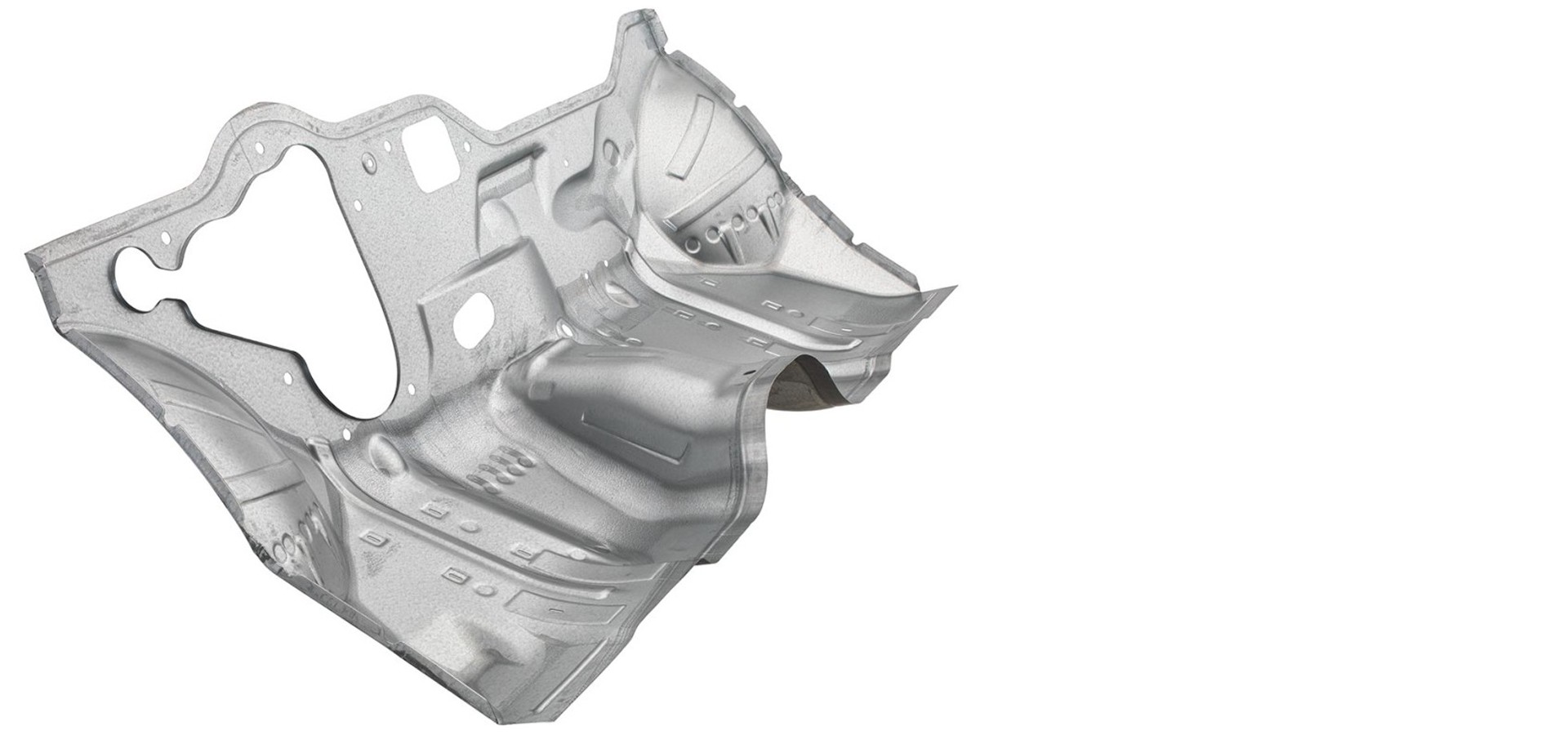

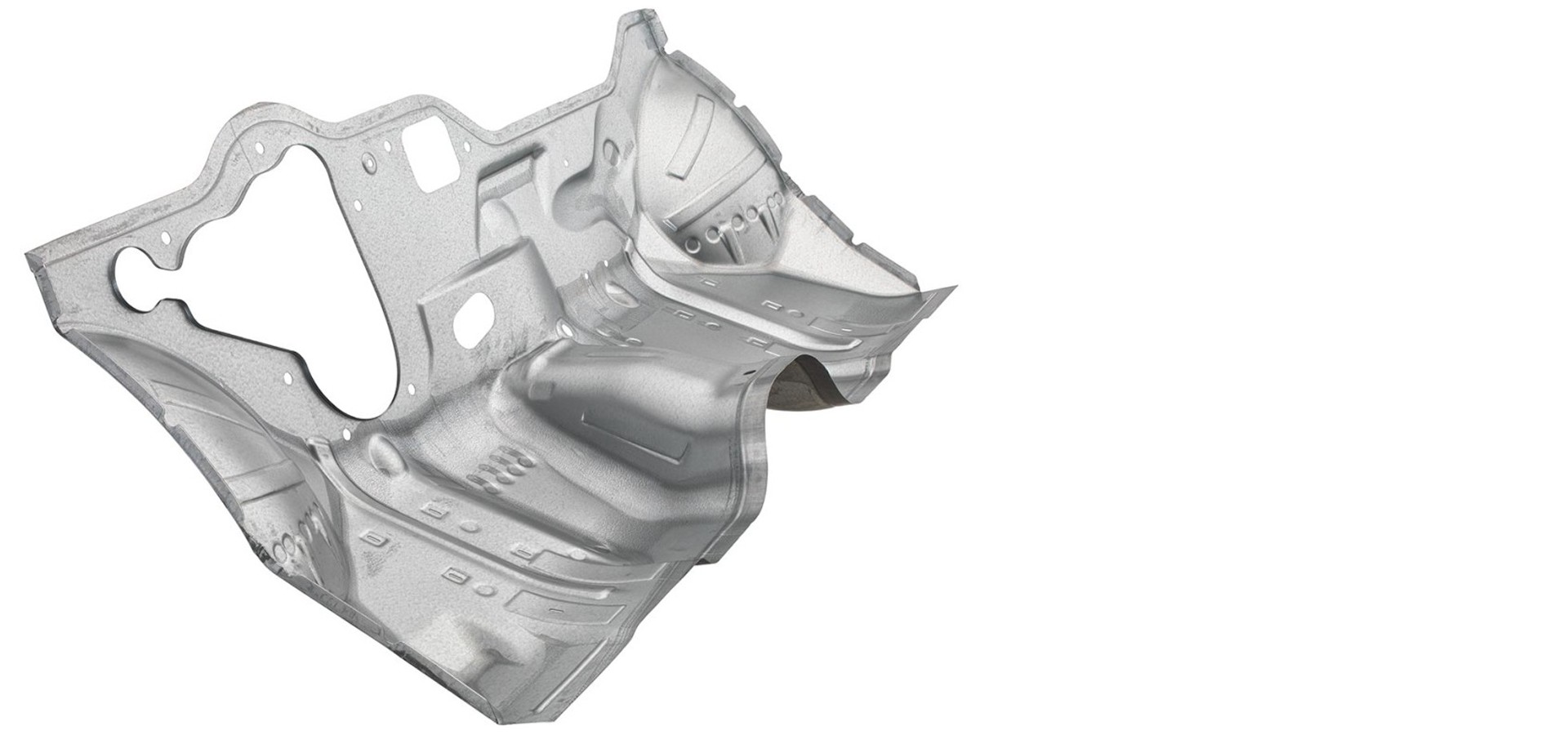

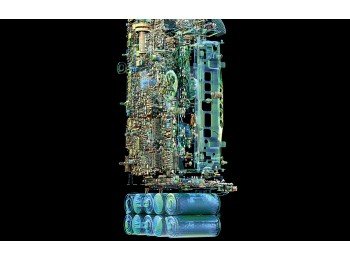

Mold - Process Design

The "FASTFORM Advanced" module will analyze your mold design in a fast and easy way, predicting the defects that may arise in the final product before the mold is produced, and save its user time and money. It allows the manufacturer to review the mold and the process, taking into account die geometry, material properties and friction, as well as molding-specific mechanisms such as springback.

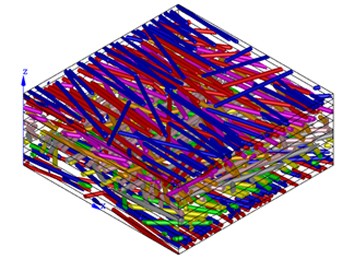

Process Planning

You can prepare your production plan in detail in "ProcessPlanner". With this module, you can define and sort the different techniques used in sheet metal forming, calculate required inputs such as minimum force, observe the costs of molds, other production tools and the entire process.