Aviation supplier FACC is testing winglets for the

A350 XWB with imc measurement solution

© Photo: CoLT

The Austrian company FACC Operations GmbH and its subsidiary CoLT Prüf und Test

GmbH, develop, manufacture and test lightweight components for leading aircraft and

engine manufacturers. Due to their expertise as system partner for winglet concepts,

they were commissioned by Airbus to design and manufacture winglets for the A350 XWB long-haul aircraft.

Of course, extensive component testing of winglets also belongs within their range of services. For the component test stands FACC and CoLT have chosen test and measurement solutions from imc Meßsysteme GmbH.

Small tips, big impact

If you can get the hang of it, many things are easier. This is true on the ground as well as in the air. A particularly dynamic upward curva- ture occurs on the blended winglets of the A350 XWB long-haul aircraft – with a smooth transition from the wing to the winglet.

Increases in profitability

Not only do the winglets provide a visually striking appearance, but they also provide an increase in terms of efficiency. The winglets expand the area of wings without increasing the overall wingspan of the aircraft. This pro- vides for less induced drag and lowers the drive-fuel consumption. In addition, the wing- lets can contribute to better stability around the vertical axis and provide for a better climb rate, as well as reducing aircraft noise.

FACC: Winglet system partner

It goes without saying that the aircraft manu- facturer made the supplier choice on the basis of competence and innovative strength. This being said, Airbus commissioned the experi- enced winglet manufacturer FACC Operations GmbH with the development and manufac- ture of the winglets for their A350 XWB long- haul aircraft.

The service range also comprises for the test and measurement of the winglets. For exten- sive component testing, FACC has chosen measurement solutions from imc Meßsysteme GmbH.

CoLT: Component testing with imc

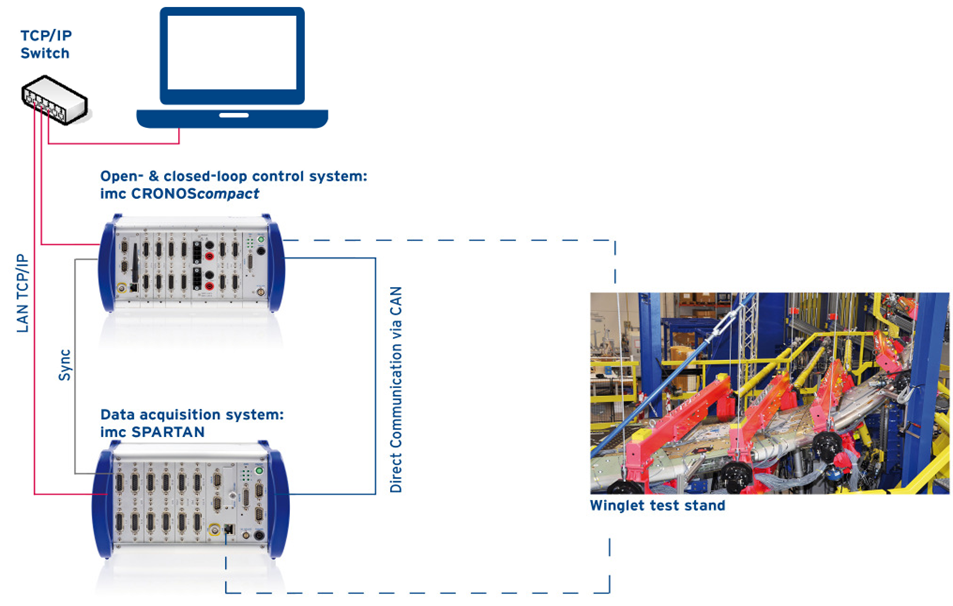

The full-scale tests were led in-house by FACC’s subsidiary Colt Prüf und Test GmbH. For the testing, the up to six meter long wing- let elements were tested statically and dy- namically for continuous and peak loading up to the mechanical failure of the component.

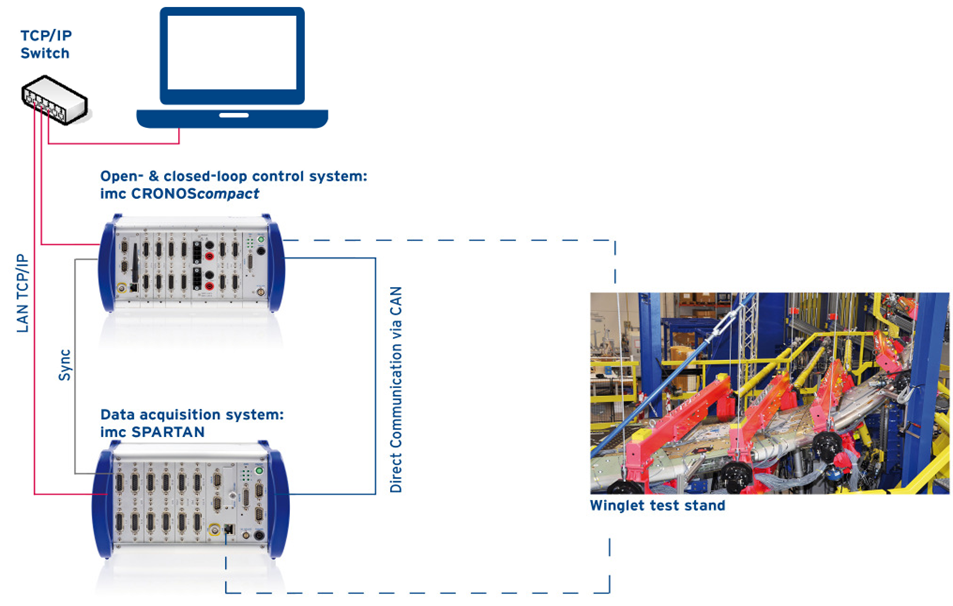

Measurement system construction: component test stand

Winglet fatigue testing

The test stand construction to support the fatigue testing of the winglet is massive: Around 110 tons of steel were used for the 10 meter test stand. The robust construction is necessary because the forces acting on the winglet are immensely strong.

15 servo-hydraulic cylinders pull and push the winglet up and down. In order to detect even the slightest expansion of the specimen, ap- proximately 600 strain gauges were distribut- ed on the mounted winglet. Ten imc SPARTAN systems and two imc CRONOScompact meas- urement systems were implemented to detect physical quantities such as strain, force, dis- placement and temperature. In addition, there is an imc CRONOScompact which over- takes the open- & closed loop control tasks. It provides for the shutdown of the load profiles and is also responsible for the control and regulation of the 15 hydraulic cylinders includ- ing force monitoring.

1200 strain gauge channels

With the imc SPARTAN, 128 channels per de- vice can be measured. Each of the 1200 strain gauge channels are continuously monitored on six different levels. Furthermore, it is pos- sible to change the strain during the three different loading scenarios to check up to 15 load points per scenario. Depending on the level exceeded, the imc SPARTAN data acquisi- tion device sends warnings or deactivation commands to the imc CRONOScompact open- & closed-loop control system which initiates a preset user freeze (a persistence on the actual load) or soft stop (slowly releasing the test object). The communication between the data acquisition devices and the open- & closed- loop control systems takes place via the CAN bus, as well as some digital inputs/outputs.

In addition to the 1200 strain gauge channels, there are 3350 virtual channels (these are calculated channels) that can provide data visualization.

Measurement results in real time

Measurement device: imc SPARTAN

The imc SPARTAN is especially productive by utilizing the imc Online FAMOS integrated real-time analysis in the measurement system.

With imc Online FAMOS, time-synchronous and deterministic cross-channel mathematical calculations, applied statistics, comparisons or sophisticated control and regulating algo- rithms can be calculated and executed. Thus, imc Online FAMOS saves time and money, since a subsequent analysis can be omitted entirely or can be significantly reduced.

Everything is under control

The test team included ten engineers and technicians, who were responsible for the calculations of the strain results and observed the behavior of the winglets during compo- nent testing. The team realized the visualiza- tion of the channels with the imc STUDIO measurement software platform.

Safety, efficiency and precision – the core characteristics that distinguish the innovative A350 XWB winglet could be verified by com- prehensive component testing.

Monitoring in the control room, Photo: CoLT

Additional Information:

BİAS Mühendislik

12/2 Altunizade, Uskudar 34662, Istanbul, Türkiye

Phone: +90 216 474 57 01

E-mail: [email protected]

Internet: https://bias.com.tr/

BİAS Mühendislik was established in 1997 and is one of the well-established engineering companies in Türkiye, offering advanced engineering solutions in mechanical engineering disciplines. Its main fields of activity are mechanical design, product development (R&D), analysis/simulation, design verification and testing services, and sales of engineering software (CAE), test and measurement systems, pre-sales and after-sales services.

BİAS Mühendislik is the only authorized representative of IMC Test & Measurement in Türkiye.

Additional Information:

imc Test & Measurement GmbH

Voltastr. 5, 13355 Berlin, Germany

Website: https://www.imc-tm.com/

FULL PRODUCT RANGE CATALOGUE: https://bias.com.tr/storage/media/4325/imc-product-catalog.pdf

IMC Test & Measurement GmbH, based in Germany, is one of the technology companies that produces application-specific solutions in the field of data acquisition systems, sensors, telemetry and test stand systems, etc.

IMC company products have been preferred in many sectors in Türkiye, especially in automotive, defense, aviation, rail systems, energy, white goods, and construction for many years.

For further technical details and application examples, you can refer to the relevant web page titled “Winglets Testing – Wing End Components” published by imc Test & Measurement, available at the following link:

https://www.imc-tm.com/download-center/application-notes/winglets-testing-wing-end-components