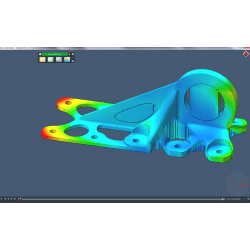

A- For Metal Material 3D Printer: Simufact Additive Manufacturing

5 main reasons to choose Simufact Additive:

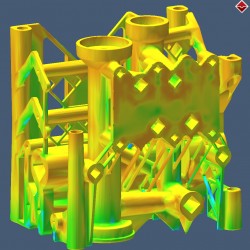

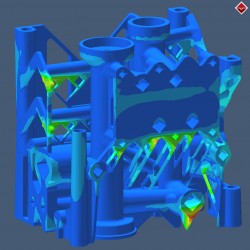

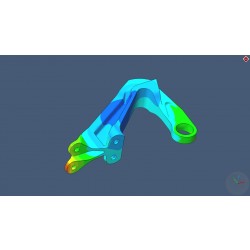

1) Troubleshooter: Solves your toughest problems with 3D Metal Printing.

It significantly reduces distortion problems.

It reduces residual stresses against the possibility of deterioration.

It optimizes the manufacturing direction and support structures.

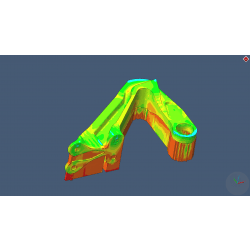

2) Powerful Concept: Thanks to the multi-scaling of Simufact Additive, the best approaches are combined on a single software platform, with the extremely fast mechanical method, fully combined thermo-mechanical transient analyzes are performed with high accuracy.

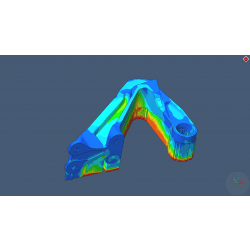

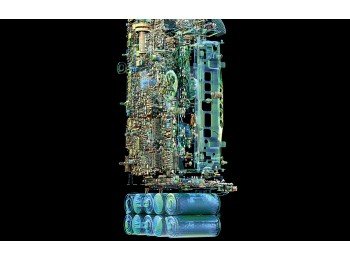

3) Specialized Solution for Additive Manufacturing: Simufact Additive is a special software solution for process simulations specialized in additive manufacturing.

4) Best Graphic Interface: It is the software that is easy to use and has the best graphic interface in its class.

5) Advanced Technology: Simufact Additive uses the technology of MSC's MARC solver, which has proven its worth in the world.

- It is the leading solution for non-linear analysis.

- It contains a very wide scope of physics.

- Moreover, it has special solutions for additive manufacturing.

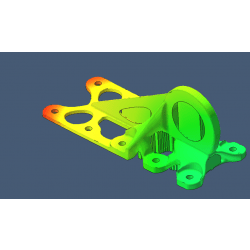

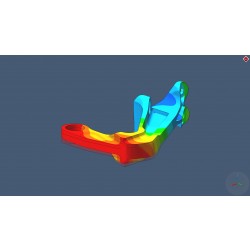

B- For the Plastics and Composites Industry: Digimat Additive Manufacturing

Additive manufacturing of plastics and composites is evolving from the rapid prototyping method to the industrial production method.

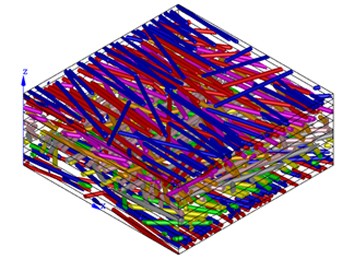

Digimat is a holistic simulation platform for additive manufacturing, offering a unique combination of material manufacturing, process simulation and structural analysis solutions.

Digimat for additive manufacturing with E-Xstream's world-renowned and highly experienced multi-scale reinforced polymer modeling technology enables accurate printing for the first time and utilizing the full potential of additive manufacturing.

Printer manufacturers:

- In addition to physical printing, you can support your customers.

- You can provide your customers with a wider portfolio of materials.

- You can support your customers for application development.

Material suppliers:

- You can better understand your materials.

- You can expand your material portfolio.

- You can support printer providers and end users to get the most out of your material.

End Users:

- You can save time and money by avoiding complicated trials and mistakes.

- You can be more confident in your manufacturing process and part design.

- For lightening, you can optimize your part performance.

Materials: Digimat enables material solutions providers and end-users of materials to develop a broader portfolio of plastic and composite materials, especially for additive manufacturing, to come up with and use different alternatives.

Digimat Products: Digimat-MF, FE and MX

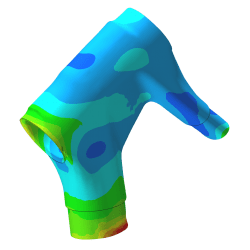

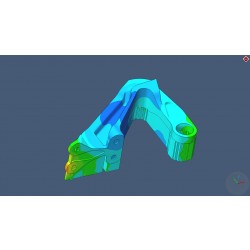

Processes: Digimat simulates the printing process, for example; By minimizing part shrinkage and residual stress as a function of material and process parameters, it helps printer manufacturers and end users identify manufacturing issues and optimize printing parameters for productivity and final part performance.

Digimat Product: Digimat-AM

Parts: Digimat enables to predict the performance of the manufactured part so that it can fully understand its final mechanical properties and assist in performance optimization for mitigation.

Digimat Products: Digimat-RP, CAE, Map