Earthquake shaking tables are systems that simulate earthquakes on the material or structural system by applying earthquake data, random earthquake data or previously formed data.

The system can apply sinusoidal, triangular, square, etc. which defined by the user in a single or multi-axis manner to defined waves and any acceleration or position profile.

Earthquake Shaking Table Usage Areas of Double and Single Axis:

- Engineering Faculties of Universities

- Tests of structural mechanics, earthquake, geophysical ground mechanics

- Laboratories of Earthquake Engineering

- Calibration of Acceleration Sensor

- Real Earthquake Tests

Earthquake Shaking Table consists of three main parts. These are;

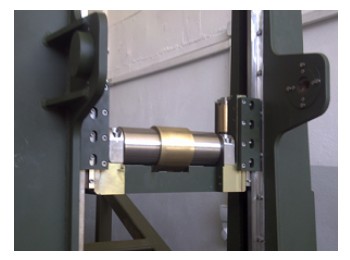

- Mechanical Structure

- Hydraulic Power Unit and High Sensibility dynamic Moog Servo Valve

- Controller Hardware and Software

- The mechanical system has a standard body produced in a structure that can with stand static and dynamic loads with high stiffness (rigidity) at high loads. Apart from standard sizes, it can be offered in different sizes and load capacities to meet the needs of extra testing and movement space.

- Hydraulic power systems are specially manufactured to provide dynamic performance for seismic test systems operating with hydraulic oil pressure and flow. Depending on the actuator, the system reaches the desired dynamic load capacity at 280 bar system pressure with variable flow as standard.

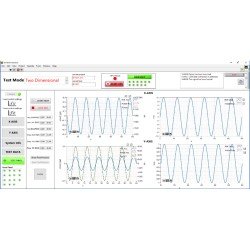

- Optest Seismic Controller is a control software designed to set up and perform laboratory-based seismic proficiency tests and earthquake simulations on structural systems, infrastructures and non-structural equipment systems. It combines a suite of innovative seismic simulation tools into an integrated application suite to enable precise control of complex, multi-channel mechanical test systems.

Software of Control Panel runs via a computer and it can carry out;

- Force PID Control

- Measurement PID Control

- Acceleration PID Control

Our Standard Table dimensions are shown below. In the Earthquake Shaking Table, customized solutions can be offered in load capacity, stroke dimensions and table dimensions.

DUAL AXIS |

Table Dimensions | m | 3 x 3 | 4 x 4 |

Maximum Stroke | mm | 250 | 250 |

Number of Hydraulic Pistons | number | 2 | 2 |

Operating Frequencies | Hz | 0-50 | 0-50 |

Maximum Load | tons | 10 | 35 |

Maximum Acceleration | g | 1 | 1 |

Maximum Speed | m/s | 1.2 | 1.2 |

Control | axis | 2 axis closed loop | 2 axis closed loop |

SINGLE AXIS |

Table Dimensions | m | 1.5 x 1,5 | 3 x 3 |

Maximum Stroke | mm | 200 | 200 |

Number of Hydraulic Pistons | number | 1 | 1 |

Operating Frequencies | Hz | 0-50 | 0-50 |

Maximum Load | kg | 2 ton | 10 |

Maximum Acceleration | g | 1g | 1 |

Maximum Speed | m/s | 1 | 1 |

Maximum Speed | axis | 1 axis closed loop | 1 axis closed loop |