Digital Image Correlation (DIC) System Application

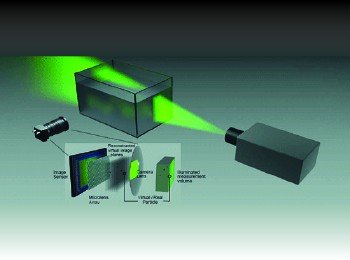

Digital Image Correlation (DIC) is a 3D full-field, non-contact optical technique to measure contour, deformation, vibration and strain on almost any material. The technique can be used with many tests including tensile, torsion, bending and combined loading for both static and dynamic applications.

The DIC method can be applied from very small (micro) to large testing areas – and the results are readily comparable with FEA results or strain gauges.

The video below shows a Ball Inflation Test with an 8 Multicamera Digital Image Correlation System, the test was developed in partnership with the University Ljubljana – Faculty of Mechanical Engineering.

Features

- 3D, full-area displacement and strain measurement on real-time image

- Ensuring that the data can be evaluated and displayed by different equipment by taking the results as real-time analog voltage output.

- To be able to measure the surface of the part in 360 degrees (front, back and side surfaces) simultaneously with multi-camera support

- Supporting a wide range of areas from less than 1 square millimeter in size to areas up to several square meters wide

- Fast and automatic calibration method

- Precision and quality values can be observed at the end of the measurement

- Presentation of all data within a certain confidence interval (error approximation)

- Access to all data in open code format

- Synchronous recording of analog data

- Expanded export and import (to finite element analysis programs for comparison or to Excel files to create tables)

- Ability to define different (user defined) coordinate system

- Measuring up to 1,000,000 frames / second through high-speed cameras

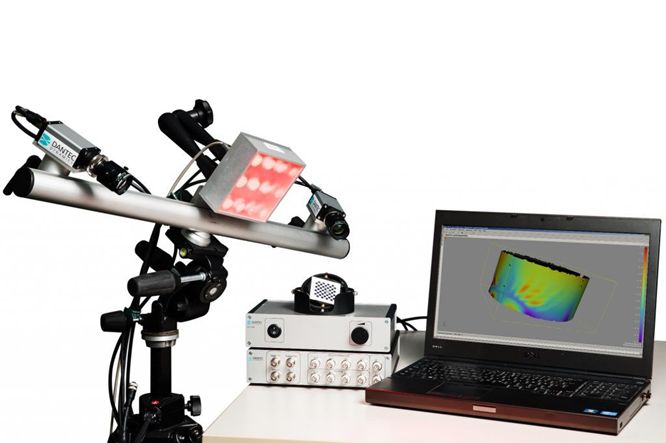

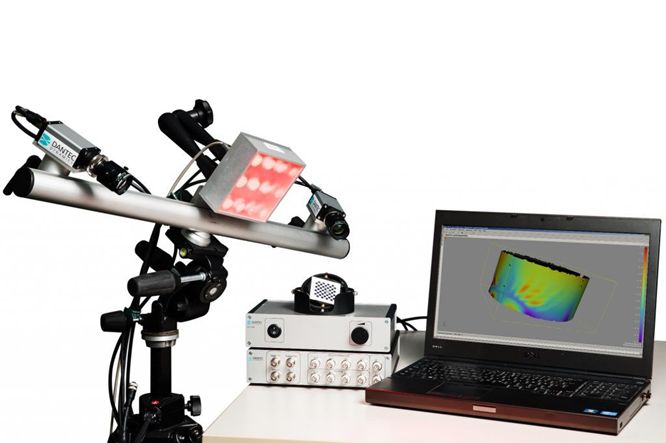

Standard 3D DIC

The Digital 3D Image Correlation System Q-400 is an optical measuring device for true full-field, non-contact, three-dimensional measurement of shape, displacements and strains on components and structures made from almost any material.

The Q-400 system is used for determination of three-dimensional material properties in tensile, torsion, bending or combined tests. In addition, deformation and strain analysis can be applied to fatigue tests, fracture mechanics, FEA validation, and much more.

A Wide Range of Applications

The Q-400’s flexible design enables a wide range of applications from microscopic investigations on microelectronic or biomedical materials to large scale measurements of aerospace, automotive, marine and railway components.

- Advanced materials (CFRP, wood, fiber injected PE, metal foam, rubber, …)

- Component testing (shape, displacements, strains,…)

- Material testing (Young’s Modulus, Poisson’s Ratio, Elasto-Plastic Behaviour)

- Fracture mechanics FEA validation

- High-Speed applications (dynamic measurements, transient events)

The Q-400 DIC evaluates data in real-time and enables the user to export data simultaneous as an analog voltage signal.

EduDIC is a complete Digital Image Correlation (DIC) measurement system, designed as a simple and convenient educational training tool for academic courses in experimental solid mechanics. This easy-to-use system allows academic instructors to effectively present the optical measurement technique of DIC for materials testing to the engineers and scientists of tomorrow.

The EduDIC system is designed with minimal hardware components, thus making connection easier and setup quicker. USB cameras operate in master/slave camera mode, which is a special configuration that does not require connection to an external triggering box. An EduDIC system can even be retrofitted with 3, 4, and even up to 8 cameras! If your application requirements change, an external triggering box and Tower PC can also be added to the system.

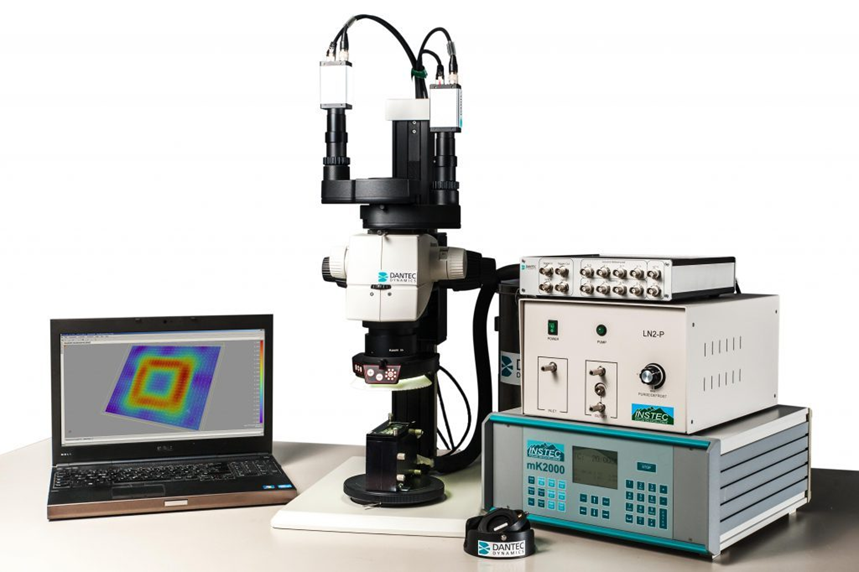

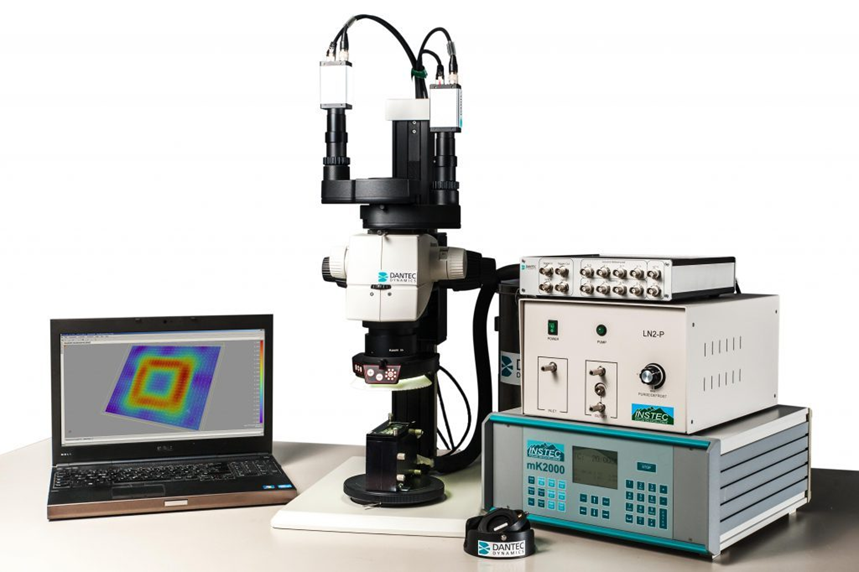

MicroDIC (μDIC)

The Q-400 μDIC system is specially designed for measurement of warpage and thermal expansion within the micro-electronics/components industry working with electronic miniaturization and high-density package design. The solution helps to measure the precise deformation in cases where simulations are not possible or testing is a necessity. The solution comes as a complete system with stereo microscope, illumination, heating/cooling stage, 5 megapixel cameras and user friendly measurement software.

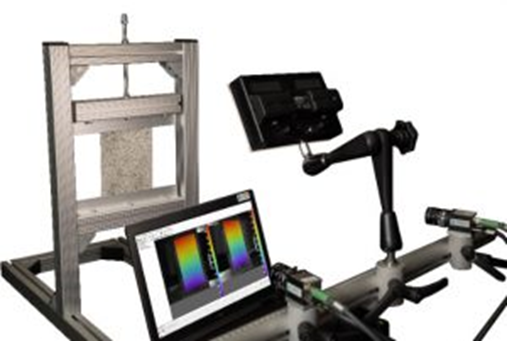

DIC TCT

The Q-400 TCT system is designed for complete three-dimensional and highly sensitive warpage, thermal expansion measurement and strain analysis of materials and components in the heating and cooling phase. Areas from 50 mm x 70 mm down to 2 mm x 3 mm can be investigated. Measurements can be done from room temperature up to 300°C and down to -40°C. The system is specially suited for thermal expansion measurement of electronic components and is frequently used in the development and testing of complex anisotropic materials, components, and structures in electronic applications.

The system is ideal for the experimental verification of analytical and numerical calculations.

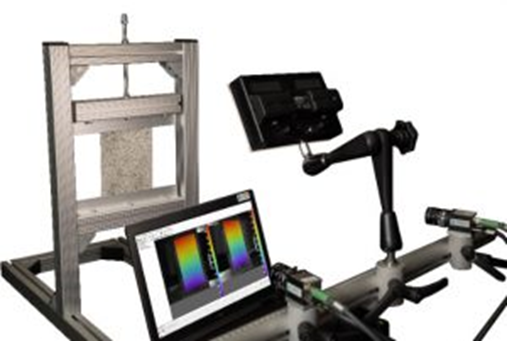

DIC High-Speed

The 3D High-Speed Image Correlation System Q-450 allows the full-field, non-contact and three-dimensional dynamic measurement of shape, displacements and strains on components and structures made from almost any material. Based on the digital image correlation technique, the Q-450 system is designed for full-field vibration analysis and high speed transient events. This makes it ideal for ballistics testing, fracture mechanics, shock excitations, the Hopkinson Bar test, or Impact Testing.

The system uniquely combines the high spatial resolution of full-field optical measurements with high temporal resolution. The dynamic range is from standstill to 100,000 Hz and has the capability to measure displacements in the 1 micron to 1 meter range. The resolution is typically about 1 micron and 0.01% tension. The system can be used for objects of any size by simply changing the optical lenses.

A Wide Range of Applications

The Q-450’s flexible design opens up a wide range of applications from microscopic investigations on microelectronic or biomedical materials up to large scale measurements of aerospace, automotive, marine and railway components.

Hopkinson Bar Test

- Advanced materials (CFRP, wood, fiber injected PE, metal foam, rubber, …)

- Impact and Ballistic tests

- Hopkinson Bar test

- Material testing (Young’s Modulus, Poisson’s Ratio, Elasto-Plastic Behavior)

- Fracture mechanics

- FEA Validation

- Harmonic or Transient events

CLICK for measurement principle details